Farming is a labor of love, whether you plant your seeds in the ocean or in the soil.

It’s one of those places that you can’t get to from here; so many great places in South Carolina are like that. Situated off Highway 17, just north of Mount Pleasant sits this sleepy fishing town. The town lines are drawn by borders of marshy sea grass along the edges of Jeremy Creek, and the roads dodge Palmetto trees that spring up wildly on the shoulders, and sometimes in the middle, of the narrow streets. Here, farmers plant seeds, nurture natural resources and bargain with Mother Nature. Their landscape just looks a little different from a “traditional” farm.

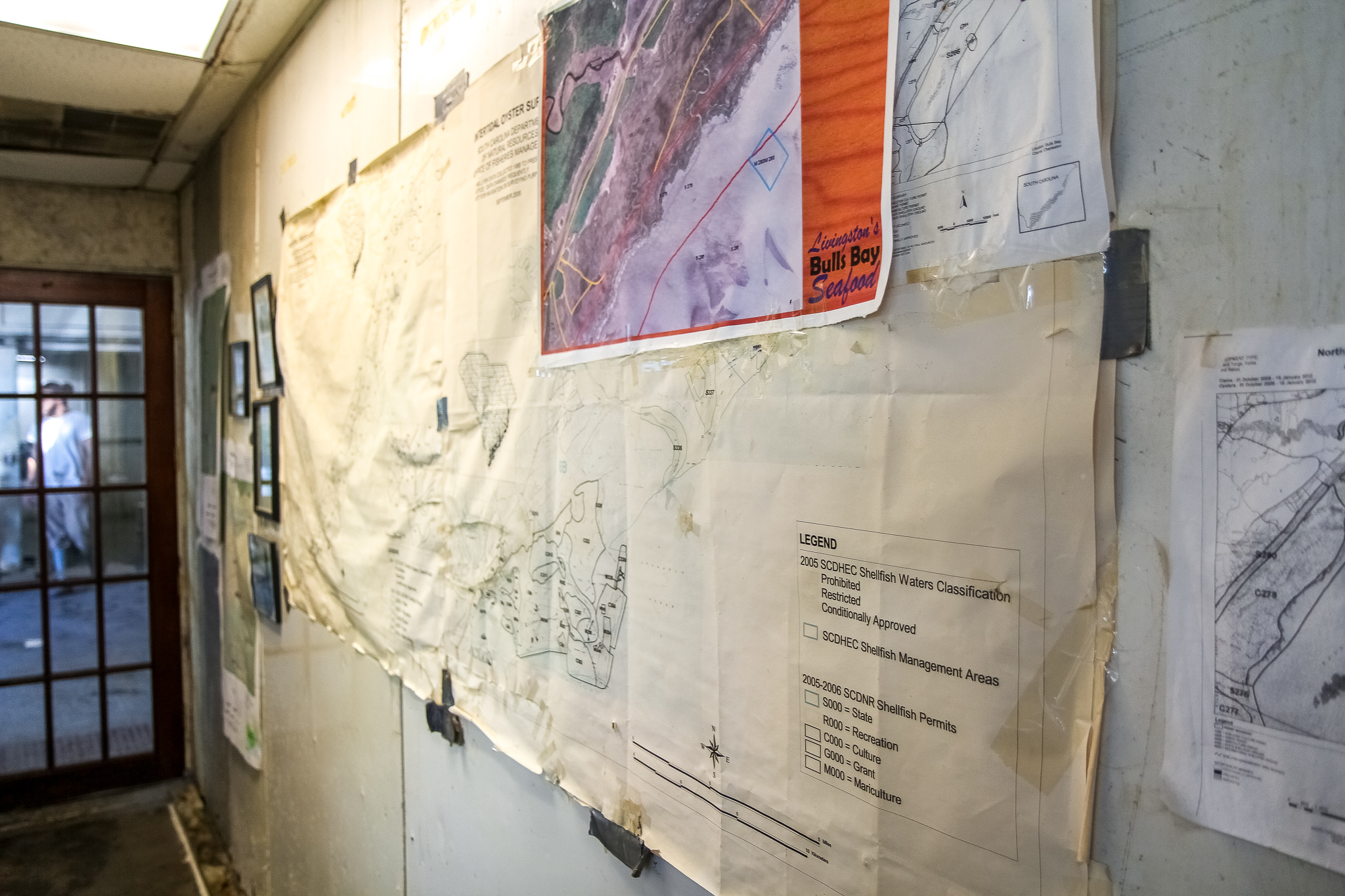

Once a vacation destination for wealthy indigo and rice plantation owners, McClellanville is now home to several fishing docks where purveyors of fresh-from-the-ocean seafood can find their fill. Down a gravel drive, you’ll arrive at the unassuming Livingston’s Bulls Bay Seafood, a third-generation seafood business specializing in farm-raised oysters and clams, wild-caught shrimp and soft shell crabs. Owner Jeff Massey joined his in-laws in the business in 1998.

“My wife and I moved down, and I started coming in to do the books for them. All they did then were shrimp and oysters,” Jeff remembers. “They dabbled in soft crabs.”

Jeff’s father-in-law encouraged him to take on a larger role in the business. Jeff saw the importance of diversifying their portfolio and suggested they look into adding clams to their offerings. The two enrolled in a weeklong intensive training held at Harbor Branch Oceanographic Institute in Florida. There, they learned the many aspects of farming clams, including hatching and spawning as well as growing algae and other conservation techniques. In 1999, Bulls Bay Seafood planted its first crop of clams and harvested them in 2001.

Just like any new crop, clams didn’t come without their share of trial and error. And, turns out, row spacing is important for mollusks, too.

“For the first ones, we did a row then left a gap, like you’re farming,” Jeff explains. “It looked like rows of potatoes. But then we started thinking, 'well you don’t really need to drive a tractor or anything out here.'”

With that in mind, and after a few hip-deep mud baths, the crew decided the best, and safest, layout was tight blocks leaving no space between each row.

Clams start as a “seed” that’s between four and six millimeters in length. Four feet by four feet mesh bags are filled with roughly 10,000 clam seeds per bag, then daisy-chained together and anchored in the mud with pipes. After about three to six months, the bags are brought in and clams counted by weight. They are returned to the water in groups of 1,000 inside grow-out bags. Clams are planted in cycles so they can be harvested year-round.

Now, for the wait. Up to a year-and-a-half. Then four million clams will be lifted from their muddy homes, triple-washed, sorted and bagged.

Jeff recommends sautéing the clams in butter, garlic and white wine and serving them over angel hair pasta topped with the sauce from the pan.

Speaking of sumptuous seafood, each spring Southerners await the arrival of soft-shell crab season, that few weeks window between March and May, or the “big shed,” when female blue crabs are molting and are perfect for eating whole. Battered and deep-fried, of course.

Crabs actually shed with each cycle of the moon, but the local “big shed” only happens once a year. During this time, female crabs in their terminal molt are selected for harvest. These crabs have already laid eggs allowing the population to continue to thrive. Males have usually moved out to sea during this molt, so the rare male crab is used as bait.

“We look at it like this: everyone wants to go to the prom. And everyone wants a date,” says Jeff.

Bulls Bay constructed a greenhouse to be used as a shed house. The inside is lined with tanks, each of which will be filled with 300-500 blue crabs. The crabs stay in the tank until they “bust” or get a hairline crack in their shell. Once they’re busted, they’re moved to buster tanks, then on to a soft tank. Crabs have to be kept isolated because if they’re different from the others, they will kill each other.

According to Jeff, “Georgetown crabs are crazy.”

Similar to clams, oysters are also planted as seeds. Jeff works with a neighbor who starts the seed in a pond in floating cages. When they’re ready, the oysters are transferred to bottom cages where a strong water flow prevents barnacles from growing on the shells.

Some oyster farmers along the coast use floating cages. As with other types of agriculture, practices depend largely on the area in which you are cultivating, as well as access to land – water in this case – and workers.

When the oysters are harvested, food safety regulations require that they be cooled to 50 degrees within two hours. They are rinsed and then run through an oyster cleaner, which Jeff likens to their version of a cotton gin. The spinning pipe tosses the oysters as they are sprayed with cool water to clean them while simultaneously lowering their temperature. Barnacles and empty shells are bounced off the clusters where they are collected and will be returned to the creek as nourishment for oyster beds.

Bulls Bay runs with a small workforce. This particular sunny October day, just three men were handling the business of cleaning, sorting and bagging.

“I’ve done my time on the boat,” quips Jeff. “Now it’s their turn.”

The team of three works in tandem. Jamie shovels the clusters into the pipe; Kenzie scrapes them out the other end into a basket; Caesar dumps the full baskets into woven bushel bags. They follow a similar process for sorting clams. Jamie feeds the clams down the chute while Kenzie fills the mesh bags – 200 clams in each. Caesar does quality control and checks for broken shells, then clasps the bags together before moving them onto a pallet, ready for sale.

The oysters and clams are headed for restaurants up the South Carolina coast. Or if you’re in the area, you can buy directly from the shop.

One crop that Bulls Bay has very little control over is shrimp. “It’s like farming where you didn’t do any of the planting. You just have to hope for the best,” Jeff says. “The shrimpers left yesterday – the heatwave we had about two weeks ago drove the shrimp out to cooler waters – but they’ll be back tomorrow to try again.”

Because farmers work in partnership with Mother Nature, conservation is always a core component of a good farm plan. Farming in the sea is no different. Bulls Bay takes great care to leave habitats undisturbed and replenished. In the case of clams, the water is actually left cleaner thanks to their natural filtration abilities. They use compostable materials so if something is accidentally left behind, it won’t be of any danger to sea life. Burying the clam bags has allowed them to avoid using lines so turtles do not get tangled and trapped.

The water where they farm is owned by the state of South Carolina and they lease each area by a five-year permit. The permitting process is rigorous and requires detailed documentation about harvest practices, amounts harvested and conservation efforts. Additionally, they must pass inspection by the Department of Natural Resources, the Department of Health and Environmental Control, the Army Corp of Engineers and the Department of Agriculture to be able grow, harvest and sell seafood.

Jeff says that for his harvesters, selecting the finest seafood to pass along to their customers becomes a matter of pride. “I tell them: if you wouldn’t serve it to your friends and family, don’t bring it to me.” All farmers deal with the weather. All farmers deal with regulations.

All farmers want to deliver a safe and nutritious crop to their customers. All farmers want to leave a legacy for future generations. Farming is a labor of love, no matter where you plant your seeds.

Jeff summed it up: “We’re dirt farmers, too. Our dirt is just under water.”